Adair® Limestone: Building History Part 1

Infinitely durable, uniquely beautiful – our Adair® limestone is an integral part of many breathtaking buildings across North America. Unlike our manufactured stone and brick, Adair is quarried stone. It’s one of our most well-known products – but do you know where it comes from?

Wiarton, Ontario is located on the Bruce Peninsula in a geological area of Canada called”till veneer”. This area’s stone is “diamicton” meaning sedimentary and therefore is easy to cut and shape. Our first Adair quarry was opened there in 1968 (before moving to its current location up the street.) The Wiarton area features a large concentration of dolomite limestone, the stone we harvest and finish to become Adair products.

In the early years, only one colour was extracted from the quarry: blue grey. And, at the time, extraction techniques were not advanced and so the dolomite rock was extracted via air drills and blasting. Our second quarry, the Crow Quarry, was opened in 1979, followed by the Thompson and Gatis quarries. All of these new quarries were opened in close proximity to the original site (and with similar rock formations) to maintain a consistent Adair product. Today, over 150 hectares of land is licensed for extraction with 70% of that area remaining; that 70% represents over 1,000,000 tons of stone!

Why do we go to the trouble of a extracting, shipping and finishing stone when we have so many manufacturing capabilities? Arriscraft has always recognized the importance of limestone – not only for the architectural community, but for all of us. Limestone products, like Adair, help create the museums, hospitals, universities, and other incredible places that last for generations. And, as a high performance, durable stone, Adair is a perfect compliment to Arriscraft’s premium brick and stone products.

For the past 50 years, we’ve made continuous investments to both our resource sites and finishing equipment to ensure that Adair is readily available to the design community. In the late 1980s, blast extraction was ceased and Arriscraft began using a highly efficient saw for extraction. By 2001, the first electric chainsaw was introduced. And, in 2012, we upgraded to a Predator chainsaw to further boost our efficiency and production. Last year, Arriscraft purchased a second chainsaw to increase output.

At our finishing facility, in Cambridge, Ontario, we recently invested in a state-of-the-art, fully automatic TB1600 saw. This new saw system features intelligent controls for efficient and precise cutting. Most importantly, the TB1600 is renowned as the premier cutting system for sedimentary stone, such as limestone. These advanced capabilities allow us to provide a diverse range of Adair® limestone products with tight dimensional tolerances. In our Part II article, we’ll go over the robust Adair product line, including a gorgeous gallery!

Before you go:

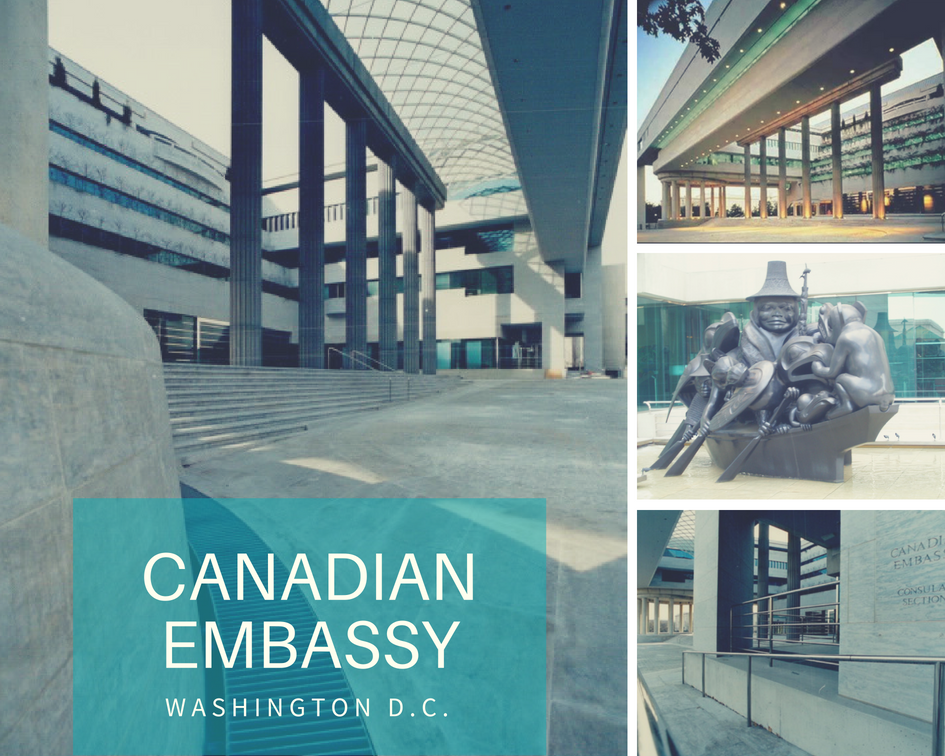

One of the first, high profile architectural projects to feature Adair® was the Canadian Embassy in Washington D.C., completed in 1986. The audacious and impressive project was designed by famous Canadian architect Arthur Erickson and its unique features are intended to be a reflection of Canada. Long horizontal stonework coupled with open spaces and water features highlight and reflect the landscape and lakes of Canada.