Arriscraft Celebrates 70 Years: Part I

We’re very excited to be celebrating 70 years in business this year. To mark our anniversary, we’re sharing a series of stories about our company’s unique history. This first article covers our early years through to the 1980s, when a few hard-fought opportunities launched our company into a new era. But first our story begins with a spark of curiosity: a quest for distinction that would ignite a culture of innovation.

The Early Years: a Quest for Better

Our founder, Ed Ratcliffe was compelled to find a better product than cement-based stone for residential building. On this quest (in the late 1940s), he visited locations throughout Europe to learn more about calcium silicate stone – which combines two natural materials, sand and lime. A natural chemical process binds these raw elements together making the stone inherently strong and offering the look of quarried stone. Ratcliffe brought his learning home to Canada and, in 1949, he founded Angelstone.

Looking for access to Highway 401, Angelstone purchased a large plot of land just outside of Cambridge about 100 kilometres west of Toronto and began to produce calcium silicate building stone. The first calcium silicate product was residential brick. Ever resourceful, Ratcliffe decided to build many of the plant buildings with stone made on site. To this day, these buildings remain. Shortly after the Cambridge plant opened, Angelstone introduced Shadow Stone Building Stone. Many bungalow homes feature this classic stone in Cambridge and surrounding communities.

The 60s & 70s: Steady Growth

In these early years, all of our brick and stone was manufactured using a single press. With the ‘can do’ spirit instilled by Ratcliffe, employees were encouraged to develop and build equipment as the need arose. So as demand grew for our unique product, a second press was engineered and added in the late 70s. These two decades are notable for steady growth. As house styles evolved, new building stone designs were introduced, and the company expanded its market more broadly throughout Ontario and into Quebec.

Keenly interested in expanding the company’s product offering, Ratcliffe purchased a new dolomite mine in 1968. This limestone quarry, located in Wiarton Ontario, featured our well-known blue-grey colour and was the birthplace of our versatile Adair® product line. A second quarry was opened in 1979, followed by the Thompson and Gatis quarries, which provided more inventory and a second colour, sepia. All of these quarries were opened in close proximity to the original site in order to maintain a consistent Adair® product over the coming decades.

The 80s: Seized Opportunities

By 1985, Angelstone had a devoted employee group and a spectacular product, unrivalled in the masonry industry. However, the company was not immune from the cyclical downturns of the housing market that would inevitably slow demand every several years. This prompted management to further diversify the product offering in an attempt to protect the business and its employees.

A New Name for the Future: ‘Arriscraft’

As our sales force ventured into architectural offices, they realized that although the name “Angelstone” was well-known and respected as a residential product, it lacked perhaps the sophistication that appealed to commercial architects. In an evolutionary step, Ratcliffe decided to rename the company Arriscraft. “Arris” meaning the sharp edge where two planes meet and ‘craft’ reflecting their work as creators and manufacturers.

Adair® Debuts at the Canadian Embassy (Washington D.C.)

At this point in our history, the Adair® product line was limited to sills and ledges. This status quo would change forever, and quickly, with one high profile project: when famous Canadian architect Arthur Erickson was awarded the design of the new Canadian embassy in Washington D.C. salesperson and company ambassador himself, Jim Cassel, seized this opportunity to share his passion for Adair® limestone – convincing Erickson that no other product would do for this prestigious project.

The monumental order was made. And in the span of a year, Arriscraft staff would source the finishing equipment from Europe, extract the material in Wiarton, set up production in Cambridge, train employees, and deliver several tons of custom-finished Adair® limestone. To this day, the Canadian Embassy remains one of the most extraordinary buildings on Pennsylvania Avenue. For Arriscraft, this contract marked the beginning of our involvement in dozens of prestigious buildings across North America, including the National Law Enforcement Officers Memorial, the United Brotherhood of Carpenters and Joiners Headquarters, the Korean War memorial (Ottawa), the Montreal Symphony House, the National Museum of Health & Medicine, and many others.

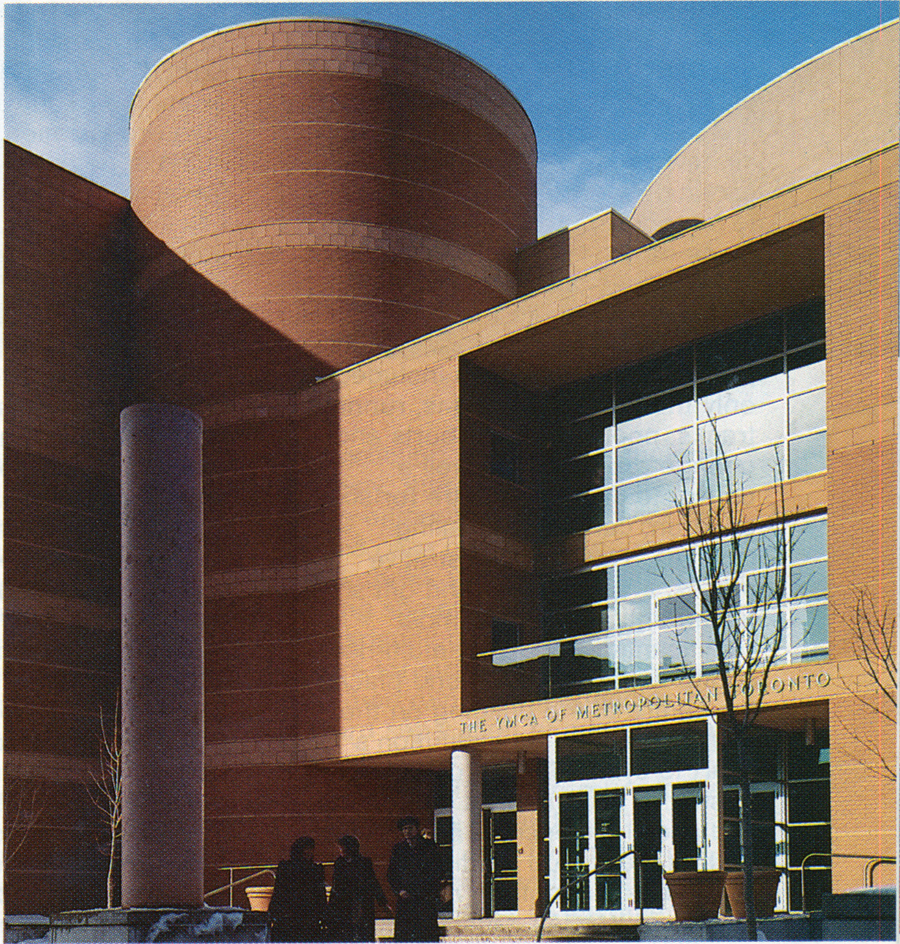

Renaissance® Stone Created for Toronto YMCA

During this push into commercial design, another key product emerged from another seized opportunity. Great sales people can sell an idea, particularly when they have immense faith in their product. So, when architect Jack Diamond was looking for an alternative to natural limestone for a new YMCA in Toronto – in particular, a smooth stone in a rust color – of course it could be done! Jim Cassel brought the challenge to the production team and our Renaissance stone was born. As you may know, Renaissance® means ‘rebirth’. And, no other product name so fittingly defines the impact this revolutionary product had for Arriscraft.

Pushing the Envelope in the Residential Market

On the residential side, we introduced Citadel® Building Stone during the 1980s. While not immediately embraced, our sales team (again) believed in its potential and saw that large production builders presented another opportunity to expand our customer base. Already known for sills and keystones, sales staff managed to make a start. Monarch Homes agreed to feature Citadel as an upgrade, on its first golf course community project in Burlington, Ontario. This immediately popular stone was featured on 5 of 10 home models and presented the customer with a new up-sell opportunity. The rest, as they say, is history – Citadel being our most popular building stone over the last four decades.

These key developments of the 1980s positioned Arriscraft as a stone products leader, in both the residential and commercial markets. The 1990s would bring a host of new opportunities and developments. Stay tuned for our next story, coming soon!