Top 5 Masonry Moisture Management Tips

Enough moisture, over time, is the blight of every masonry wall. To ensure the long-term performance of a wall assembly, you must pre-plan against moisture infiltration and set-up moisture drainage properly. Otherwise, the potential for wall deterioration greatly increases.

Moisture Management Strategies

A variety of strategies can be implemented during the design and construction of a masonry veneer that will help ensure better performance over the long term.

1. Control the passage of water vapour through the wall to prevent moisture from condensing within the wall assembly.

Moisture will typically travel through a wall due to the mechanisms of vapour diffusion and/or air movement. Installing a vapour retarder membrane will minimize the effects of vapour diffusion from areas of high humidity to areas of low humidity. Designing and constructing an air barrier system (as a part of the wall assembly) controls moisture travelling across a wall due to air movement. Typically, it is best to locate the air barrier within the assembly to ensure it is structurally ridged and protected from subsequent damage. Placement and location of the vapour retarder and air barrier will depend on the geographic location of the building and the anticipated set of design conditions.

2. Minimize the quantity of water that contacts the exterior wall

Minimizing water contact is particularly challenging near the top of buildings. The following guidelines will help minimize this risk:

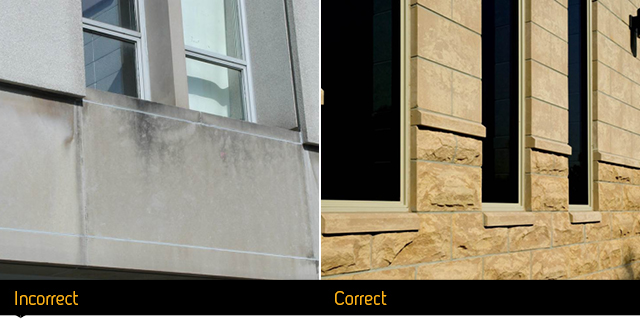

- Use cap flashings at windowsills, roof parapets and other horizontal masonry surfaces and ensure that overhangs and drips are provided to drain the water away from the wall

- Ensure that metal cap flashings are properly lapped and sealed against water leakage and always provide an under-cap flexible flashing membrane between the metal and the sub-assembly

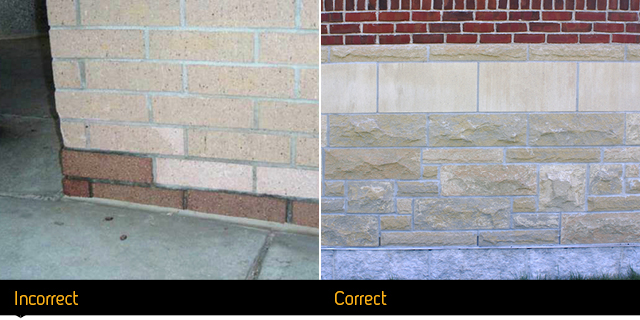

- Keep the exterior wythe of masonry at least 150 mm (6”) above finished grade or provide some other design element that will segregate the masonry from moisture laden soil

- Do not drain water from a sloping roof or skylight directly onto the wall’s surface. Use architectural elements such as gutters, overhangs, downspouts, etc., to properly drain water away from the wall

- Consider providing roof overhangs to reduce the quantity of water coming into direct contact with the wall

- Eliminate water spray from ground sprinkler systems

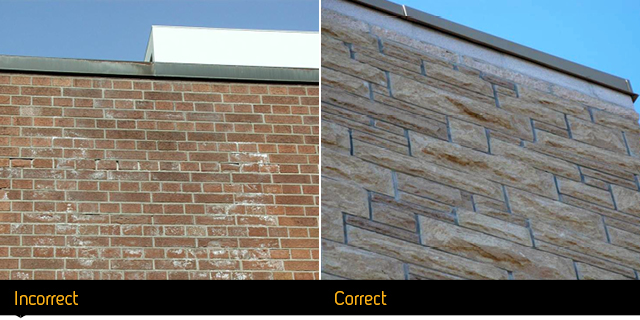

Applying a proprietary water repellent coating to the surface of the masonry veneer is an unacceptable substitute for proper design and construction. These coatings, even if described as “breathable”, inhibit the natural evaporative properties of the masonry units, causing them to remain wetter longer, particularly if the source of moisture is from within the wall assembly. Such coatings have been known to contribute to wall deterioration and could result in costly repairs.

We caution building designers not to rely upon the application of a water repellent sealer to replace good masonry wall design and construction methods.

3. Ensure the integrity of the joints and junctions in the exterior wall

Minimize the potential for moisture infiltration of the wall with the following guidelines:

- Ensure that movement joints and junctions between dissimilar materials are properly designed, constructed and maintained

- Minimize joints between sills, caps, copings and water table units by using the maximum lengths possible and ensure joints are properly sealed with a good quality backer rod and joint sealant

- Design walls to avoid cracking of joints by strategically placing properly constructed movement joints in the building veneer

- Ensure the proper design, construction and maintenance of metal parapet wall caps and/or flashing membranes

- Ensure head and bed joints are filled solid with mortar and that the mortar joint has been tightly compressed and tooled to a well-weathering profile

4. Neutralize the forces that can move water through openings in walls

Wall assemblies should be designed and constructed in accordance with the following:

- Reduce the air pressure differential by applying the rain screen principle to the design of the wall assembly

- Provide overhangs and drips at flashings and sills to direct water away from masonry materials

- Slope surfaces (at least 1:12) which are likely to retain water to make them drain water away from the wall

- Overlap materials to counter effects of the momentum of water, e.g. by lapping the building paper over the vertical leg of the flashing membranes to ensure the continuity of flow of the moisture.

5. Drain moisture that does enter the wall to maintain the weather-resistant nature of the wall assembly and to avoid prolonged saturation of the masonry

- Ensure that a clear draining cavity at least 25 mm (1”) in width exists between the masonry veneer and the other wall components

- Provide flashing membranes in the cavity over openings, at shelf angles and at the foundation level to drain any water that does enter the cavity

- Provide drainage openings, such as weep vents, regularly spaced above flashing membranes to let the water quickly exit the wall assembly

Click to view our full Arriscraft.NOTE on Moisture Management.