ARRISCRAFT: a Green Perspective

In this new millennium, environmental practices and performance have become more than ideals. Words once reflected in vision statements have evolved into carefully measured and reported data on everything from energy usage to product emissions. Regulatory compliance, demand for green products, plus rising resource and utility costs have elevated manufacturers’ environmental considerations and practices to new levels, as keys to remaining competitive and surviving long-term. From its very beginning (six decades ago), Arriscraft pioneered environment-friendly processes and embraced a culture of continuous improvement to set out as, and remain, an industry leader.

Industry Recognition

According to leading institutes in North America, Arriscraft is very well positioned in terms of overall environmental practice. In 2013, Arriscraft received the Environment Award – Excellence in Energy Conservation (at the annual Business Excellence Awards for the Cambridge, Ontario Chamber of Commerce). This environmental award recognizes a business that embraces sustainable best practices and outstanding programs to maintain, protect and promote a healthy environment. In particular, Arriscraft was cited for its efforts to conserve energy, having reduced its kilowatt-hours per 1,000 kilograms of material produced by 23 percent since 1999.

Arriscraft has also been recognized nationally. Independent studies commissioned by the Athena Sustainable Materials Institute (http://www.athenasmi.org/), reported Arriscraft as a leader in every significant category for measuring environmental performance. A Canadian organization, the Athena Institute provides industry data and software tools for planners and manufacturers which generate essential information about the footprint of their projects or materials.

The Athena Institute focuses on sustainable building materials and improving the environmental performance of the building industry. This institute commissioned a detailed report on the Canadian brick and masonry industry that included Arriscraft calcium silicate products. The majority of the environmental impact data cited in this article has been taken from this report.

Another key measurement of environmental performance is the LEED rating system (Leadership in Energy and Environmental Design), developed by the U.S. Green Building Council. It has been recognized that buildings consume 1/3 of our total energy, 2/3 of our electricity and 1/8 of our water. LEED “promotes a whole-building approach to sustainability by recognizing performance in five key areas of human and environmental health: sustainable site development, water savings, energy efficiency, materials selection, and indoor environmental quality.”

LEED is a green building certification program that recognizes best-in-class building strategies and practices; there are five rating systems to accommodate multiple project types and four levels of certification (Certified, Silver, Gold, and Platinum). The number of points a project earns determines the level of LEED certification that the project will receive. Specifically, the LEED rating system assigns a quantitative value (or points) for an “environmental benefit”.

Although LEED does not rate building materials, products considered to be LEED-compatible have competitive advantage. Based on their qualities of superb durability, energy efficiency, exceptional life span, and timeless architectural appeal, Arriscraft products have been included in many LEED-certified projects throughout North America. As examples, the Eco-Rangers building, one of the first LEED projects in Ontario, features Arriscraft masonry and obtained Silver certification; the Markim Hall at Macalester College in St. Paul, Minneapolis, incorporated Arriscraft masonry and received Platinum certification.

Facts about our Green Products and Practices

Readily Available Raw Materials

Arriscraft has two main raw material inputs: silica sand and lime. It is important to note that both of these components are readily available and of a benign nature. “Silica sand” is an industrial term used for sand with a very high percentage of quartz (silica) grains. Natural silica stone (silicon dioxide SiO2), or quartz lumps, is a simple compound of the elements silicon and oxygen. It is the most abundant mineral on the earth. The most abundant sedimentary rock is limestone, composed chiefly of the mineral calcite. Limestone is extracted and processed into the reactive lime utilized in the Arriscraft stone manufacturing process. The vast availability of these raw materials makes the production of Arriscraft stone highly sustainable. All input materials are locally available, which means that shipping of raw material is kept to a minimum.

Arriscraft products produced in the Cambridge, Ontario manufacturing facility utilize a percentage of post-industrial recycled material. Within a given year, up to 6% of the raw material by weight may be comprised of recycled material.

In fact, only the production of lime has any real environmental consequences and suppliers have been going to great lengths to improve their environmental performance. All mineral extraction sites are in full compliance with environmental laws and great care is taken to make sure that sites are fully rehabilitated and return to their original state or better.

Controlled Water Usage and Re-use

Water contamination and waste is a very important concern when assessing environmental impact – especially considering the global water shortage quickly becoming one of the most important issues facing our global society. Arriscraft utilizes a looped settling pond system to minimize water usage. Water is fed into a pond and into the process where needed. The water from various process uses is then collected in a settling pond where the fines settle and are dredged as the pond is filled. The clean water is pumped to the original pond and re-used. The dredged material can be re-introduced into the raw material stream. Many initiatives have been introduced in the manufacturing process to minimize the amount of process water utilized. For example, in recent years, at one production facility all water-cooled compressors were replaced with air-cooled systems.

Cleaner and Reduced Energy Usage

Clean burning natural gas is used in generating the autoclave steam. By using natural gas in the production process, Arriscraft’s CO2 output is one-third of that associated with clay brick products. In the calcium silicate process, natural gas is only used to heat water and not to burn the product. Consequently, the air emissions often associated with kiln firing clay, cement or other materials are not present. Additional efficiencies in energy consumption (during autoclaving) are achieved through pre-heating autoclaves and boiler feed water with exiting steam from previous cycles.

Lower Embodied Energy

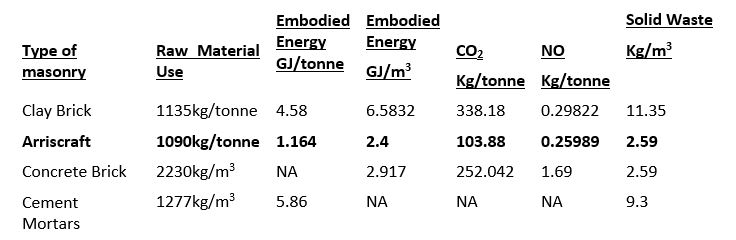

Embodied energy is a measure of how much energy is used in the production and transportation of a product. It is an important gauge in the environmental impact of a product and its manufacturing process and one of the only ways to directly compare competing products. According to the study commissioned by the Athena Institute, Arriscraft‘s calcium silicate products have an embodied energy of 1.164 GJ/tonne and 2.4 GJ/m3. To put this into perspective, clay brick was listed as having an embodied energy of 4.58 GJ/tonne and 6.5832 GJ/m3.

Active Recycling Practices

Arriscraft practices the 3R (Reduce, Reuse, Recycle) philosophy of waste reduction. Packaging materials all contain recycled content. On-site recycling includes systems for collecting plastic, Styrofoam, paper, aluminum cans, oil, antifreeze, steel, brass, bronze, and cardboard. Of the solid waste generated during the manufacturing process, a portion is re-introduced into the raw material stream and the remainder is crushed into aggregate.

Sustainability Through Durability

One of the best environmental characteristics of Arriscraft stone is its high durability. All Arriscraft stone is manufactured to adhere to severe-weathering requirements, is warranted for the lifetime of the building and requires relatively little maintenance over its lifetime.

Indoor Air Quality

Indoor air quality became an important issue for the building industry in the 1980s, when ‘sick building syndrome’ was first identified. When utilized as an interior finish, Arriscraft stone masonry does not emit any harmful gases.

Competitive Comparison – Arriscraft vs. Other Masonry Products

* Life Cycle Analysis of Brick and Mortar Products. Sep./98 prepared by George J. Venta, Venta, Glaser & Associates

Conclusion

In conclusion, Arriscraft is a leader in the production of green masonry units. Its entire process, from raw material extraction to finished product, has proven to be environmentally sound. The nature of the product itself has no negative ramifications on the environment. Arriscraft continues to keep environmental concerns at the forefront of its corporate policy and assumes an attitude of collective responsibility. In so doing, Arriscraft intends to remain the best producer of ‘green’ building stone on the market.